Delivered and Sealed: The Significance of Vacuum Ports in Security and Precision

In various scientific and industrial applications, precision and safety are paramount. One advancement that has steadily gained importance in these fields is the vacuum viewport. These specialized windows offer an unobstructed view while maintaining a vacuum environment, allowing scientists and engineers to observe processes or experiments without undermining the integrity of the vacuum system. This unique capability makes vacuum viewports vital in environments ranging from materials research to medical imaging.

The role of vacuum viewports extends past mere visibility; they are crucial in ensuring the stability of conditions in experiments. By providing airtight seals, they prevent interference and allow for exact monitoring of reactions and processes. Regardless of whether in a laboratory researching with new materials or in a production facility utilizing vacuum technology, these viewports serve as a critical link between observation and operational efficiency, bridging the gap between the known and the unknown in scientific exploration.

Grasping Vacuum-sealed Ports

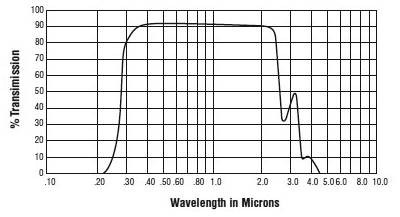

Vacuum viewports are specialized visual components engineered to deliver a unobstructed line of perspective into vacuum environments all the while upholding the integrity of the vacuum barrier. They are commonly fabricated from high-quality substances such as transparent glass or quartz glass and are designed to withstand the stress and factors of sealed applications. This makes them vital instruments in various academic and manufacturing applications where visual monitoring or monitoring is required while not compromising the sealed environment.

In many science institutes, sealed ports are used in applications such as electronic microscopy, where accurate viewing of samples is essential. Through permitting teams to effectively view components within a vacuum environment, these ports support the study of processes and the examination of materials under regulated environments. Their construction helps to reduce the effects of environmental disturbance, ensuring that findings are accurate and consistent.

Additionally, vacuum viewports play a critical role in fields such as microchip production and deposition processes. They enable operators to review activities in actual time and perform necessary changes without disrupting the sealed environment. The skill to maintain a hermetically sealed closure while providing visibility ensures both safety and accuracy, critical factors in sophisticated production and scientific purposes.

Security Precautions

Negative pressure windows serve a crucial function in upholding security in various contexts, especially in settings where hazardous materials or high-risk processes are present. The structural soundness of the viewport is crucial, as any malfunction can lead to the escape of unsafe materials or exposure to hazardous conditions. Frequent check-ups and strict quality control during manufacturing are necessary to ensure that these parts can bear the pressures they encounter.

Additionally, the material selection for negative pressure viewports significantly impacts their security capabilities. Typical substances include glass and specialized materials, which must be sufficient of withstanding not only the negative pressure environment but also likely thermal and physical forces. Adopting a solid design that considers these elements helps reduce risks, ensuring the windows function reliably without compromising safety.

Furthermore, appropriate setup and upkeep of negative pressure windows are critical for workplace security. Users must be instructed in proper handling methods and cognizant of the functional limits of the viewports they employ. Following to production instructions and security standards can help avoid incidents and contribute to a safe working space, allowing staff to concentrate on their duties without excessive worry.

Applications in Precision Work

Vacuum portals play a critical role in various fields that demand high precision and accuracy. In laboratories, they are vital in tests involving precise measurements, where even the smallest disturbance can lead to inaccurate results. By providing a controlled environment, vacuum viewports enable researchers to perform experiments with least interference, preserving the purity of delicate samples and ensuring reproducibility.

In the production industry, especially in the fabrication of semiconductors and microelectronic components, vacuum viewports are indispensable. They allow for the observation and handling of processes in vacuum conditions, which are critical for the deposition of thin films and other complex procedures. These viewports facilitate on-the-spot monitoring and inspections, enabling engineers to maintain strict tolerances and achieve the required quality in their products.

Additionally, vacuum viewports are progressively utilized in the medical field, particularly in the advancement of state-of-the-art imaging techniques. They provide clear visibility into diagnostic equipment that functions under vacuum conditions, allowing for accurate imaging without the issues that arise from atmospheric interference. This application supports reliable diagnostics and helps in the formulation of novel treatment methods, underscoring the adaptability and value of vacuum viewports in precision work across multiple industries.